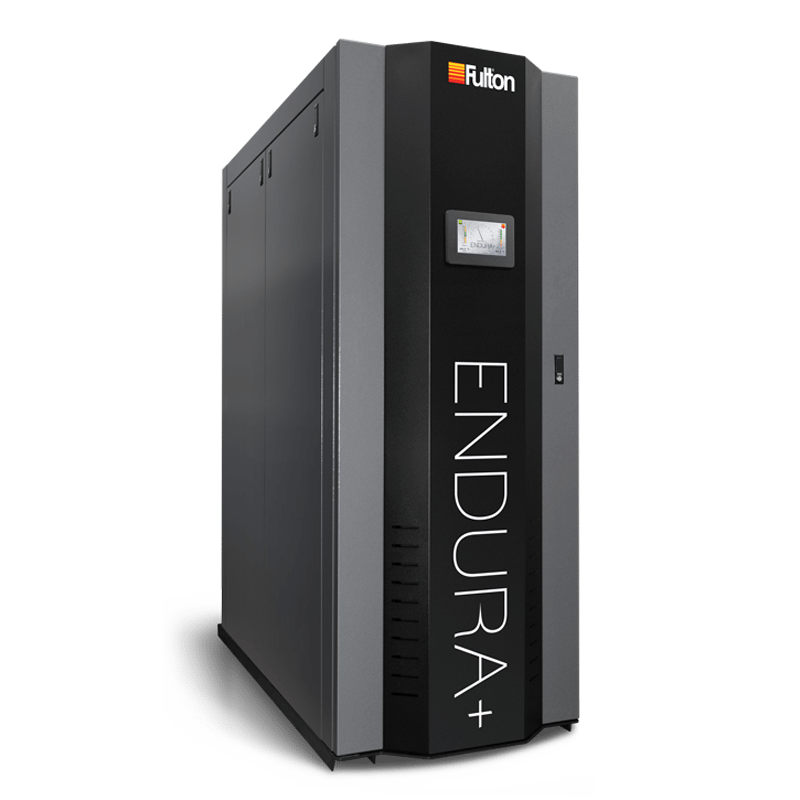

A REVOLUTION IN FIRETUBE CONDENSING BOILER DESIGN

Fulton’s ENDURA+ efficiently captures up to 99% of the fuel’s energy while intelligently directing water through engineered flow paths.

- DESIGNED FOR VARIABLE PRIMARY FLOW

- UP TO 15:1 TURNDOWN; O2 COMPENSATION

- NATURAL GAS PRESSURES DOWN TO 4″ WC

EASE OF INSTALLATION, OPERATION & SERVICE

PURE Optimized to fit an ultra-compact footprint, the ENDURA+ surpasses the reliability of existing boiler designs and is easier to install and service.

- FITS THROUGH A STANDARD DOORWAY

- ACCESS PANELS DETACH IN SECONDS

- SIMPLIFIED SERVICE & MAINTENANCE

OPTIMIZED HEAT EXCHANGER

Built with Duplex stainless steel, the ENDURA+ heat exchanger features higher strength, increased resistance to corrosion, and superior thermal strain management. Shown on the left, Finite Element Analysis (FEA) reveals the stark contrast in operating stresses between competing equipment and Fulton’s patent-pending design.

- COMPACT, DURABLE, AND EFFICIENT

- 23% LESS THERMAL EXPANSION COMPARED TO 316L STAINLESS STEEL HEAT EXCHANGERS

TRULY STRESS-FREE OPERATION

Conventional designs sacrifice material integrity and durability by transferring the stresses of operation directly onto the tubesheet and heat exchanger tubes. The ENDURA+ eliminates longitudinal thermal expansion stress by absorbing thermal growth externally as the heat exchanger freely expands.

- AXIAL THERMAL EXPANSION STRESS ELIMINATED

- BOILER LIFE GREATLY EXTENDED

- LIFETIME THERMAL SHOCK WARRANTY

POWERFUL & INTUITIVE INTERFACE

Engineered by Fulton for the ENDURA+, the 7-inch touchscreen control maximizes performance and facilitates commissioning. It efficiently sequences up to 10 boilers and eliminates the need for a master boiler or standalone panel. If a boiler is powered off, the cascade seamlessly transitions to the next available stage with zero downtime.

- SIMPLIFIED OPERATION

- Optimizes modular boiler efficiency with parallel sequencing and outdoor air temperature reset.

- HYDRONIC SYSTEM CONTROL

- Sequences motorized isolation valves to enhance temperature control; closes valves via delta-T ensuring residual heat is dissipated.

- BUILDING INTEGRATION

- Communicates with the Building Automation System with Modbus; BACnet configurable.

- VARIABLE SPEED PUMP CONTROL

- Automatically maintains heating water delta-T or delta-P with variable speed pump control and auto-backup rotation.

RELIABLE & EFFICIENT COMBUSTION

Fulton’s combustion technology features turndowns up to 15:1 with high-precision servo motor control, outperforming all conventional platforms. O2 Compensation tunes the fuel/air ratio in realtime, boosting efficiency across all modulation rates and automatically adjusting for seasonality.

- SMALLER FLUE DIAMETERS

- LONGER VENT RUNS

- NOx LEVELS CONFIGURABLE TO <9 PPM

INSTALLATION SIMPLIFIED

ENDURA+ boilers are designed for the simplified piping method of variable primary flow. This enhances temperature control, reduces design complexity, and maximizes condensing boiler efficiencies by delivering the lowest temperature water directly to the boiler rather than blending with heated water in a primary-secondary manifold.

- VARIABLE PRIMARY FLOW DESIGN

- REDUCED INSTALLATION COSTS

- NO DEDICATED BOILER PUMPS

- SMALLEST SERVICE FOOTPRINT

- GREATEST CONDENSING POTENTIAL