| Vertical Multi-Port(VMP) 40 -150 BHP |

| Type: Steam or Hot Water Boiler |

| Size Range: 40, 49.5, 50, 60, 80, 100, 130, 150 BHP |

| Primary Application: Laundries, Industrial / Commercial |

| Burner Available: Gas or oil fired and combination fuel fired. * Low emissions burner optional. |

| Design Pressure Range: Standard: 15, 150 psig Custom: Up to 300 psig |

| Efficiency: Up to 84 % |

FEATURES:

- Vertical 2-pass design with heavy-walled Schedule 80 flue pipes (No tubes to replace)

- Water-backed, insulated blanket surrounding the boiler results in lower radiant losses

- Small footprint – compact design

- Built/Certified to ASME, CSD-1 and other applicable codes, UL Packaged Boiler

- Low emissions burner available

- Largest vertical tubeless steam boiler available to the market

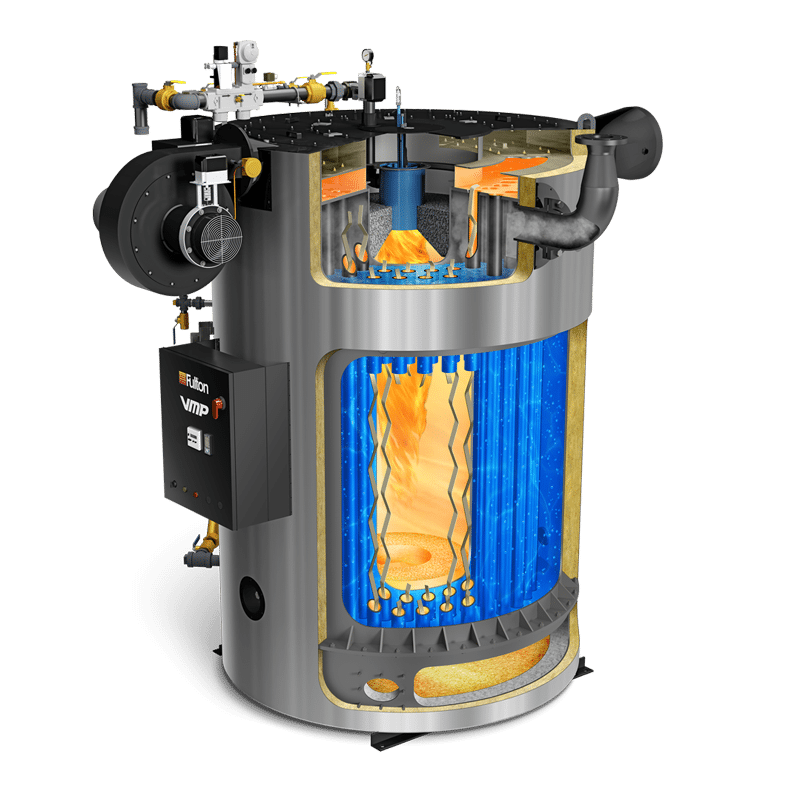

DURABLE AND RELIABLE CONSTRUCTION

Within the Fulton VMP (Vertical Multi-Port) Boiler, a series of heavy-walled largediameter Schedule 80 flue pipes are welded to the top and bottom heads in the pressure vessel, and these pipes are surrounded by water. Within these pipes are “ribboned” turbulators that maximize overall heat transfer. The water-backed design speeds up boiler start up time and creates even heating throughout. These, along with the many other design features of the VMP, result in fuel to steam efficiencies of up to 84%.

THE COMBUSTION PROCESS

- Air is drawn into the top-mounted power burner, where it is sent through the swirl plate and mixed with fuel for optimal combustion.

- The ignition assembly ignites the air/fuel mixture and sends a spinning cyclonic flame down the length of the furnace chamber, forming the first pass.

- The flue gases are turned at the base of the furnace then return through the Schedule 80 pipes, forming the second pass. The turbulators within the pipes distribute the flow of the flue gases to transmit the remaining heat to maximize heat transfer.

- The flue gases are then collected at the upper portion of the boiler and are expelled through the flue outlet.