Setting the standard…again

In 1949, Fulton pioneered the vertical tubeless design, which quickly became the industry standard for industrial steam boilers. Since that time, no one has been able to improve upon Fulton’s original design.

Now Fulton is raising the bar with the VSRT (Vertical Spiral Rib Tubeless) boiler, the world’s first fully wetted, refractory-free vertical tubeless boiler and the new standard for industrial steam boiler design.

VSRT boilers are PURE Optimized and built to last as a reliable source of clean steam, providing cost savings and operator peace of mind for years to come.

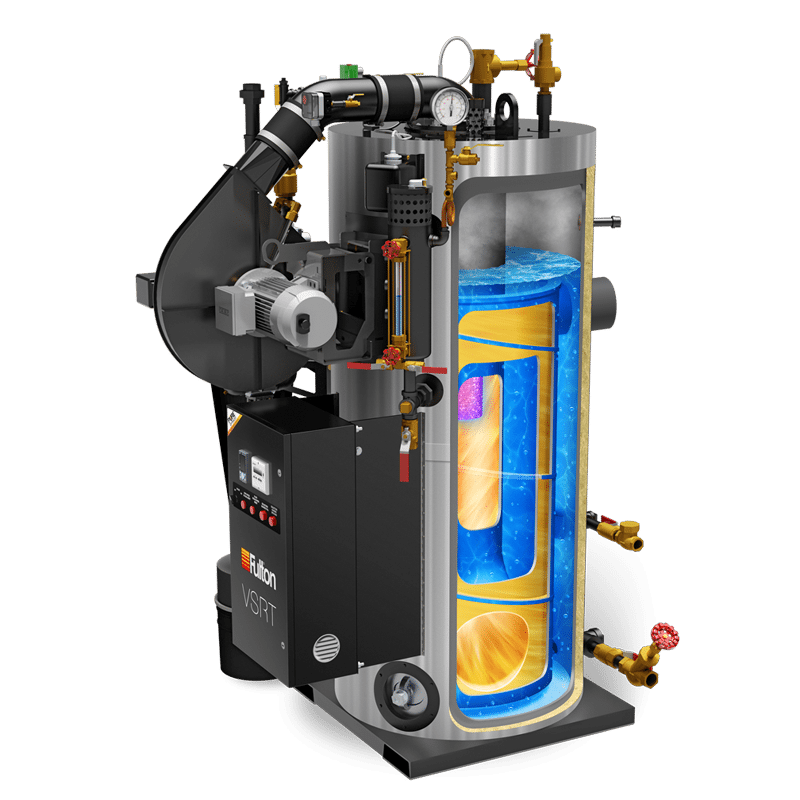

A REVOLUTION IN STEAM BOILER DESIGN

Fulton’s patent pending spiral rib heat exchanger achieves industry leading heat transfer rates. The unique spiral design provides a long heat transfer path which is optimized to achieve maximum heat transfer in a compact space. The VSRT features a fully water backed pressure vessel wrapped with high density insulation, resulting in minimal thermal losses and low jacket temperatures.

A LOOK INSIDE:

- Air/fuel mixture enters into the combustion chamber

- PURE optimized burner features up to 10:1 turndown with exceptionally low emissions

- Combustion gases transition downward from the combustion chamber into the spiral heat exchanger

- Flue gases spiral upward through our patent-pending heat exchanger 5 Flue gases exit the boiler

LOWEST OPERATING COSTS

As the world’s first and only spiral rib tubeless design, the VSRT has been optimized so that the spiral rib heat exchanger can transfer the most amount of heat in the most compact space.

- INDUSTRY LEADING THERMAL EFFICIENCIES

- TURNDOWN UP TO 10:1, FULL MODULATION

- 20 PPM NOx STANDARD

- VARIABLE SPEED FAN

- LINKAGELESS CONTROLS

DURABLE PRESSURE VESSEL

The VSRT has a patent pending, self-compensating stress relieving architecture. Our spiral rib heat exchanger is fully immersed in water to optimize heat transfer, creating a longer-lasting boiler that beats the competition in every category of durability.

- FULLY WETTED, REFRACTORY-FREE DESIGN

- THERMAL STRESSES VIRTUALLY ELIMINATED

- VERTICAL TUBELESS DESIGN VIRTUALLY

- ELIMINATES CORROSION

- 5-YEAR PRESSURE VESSEL WARRANTY; 10-YEAR WITH ENGINEERED SYSTEM

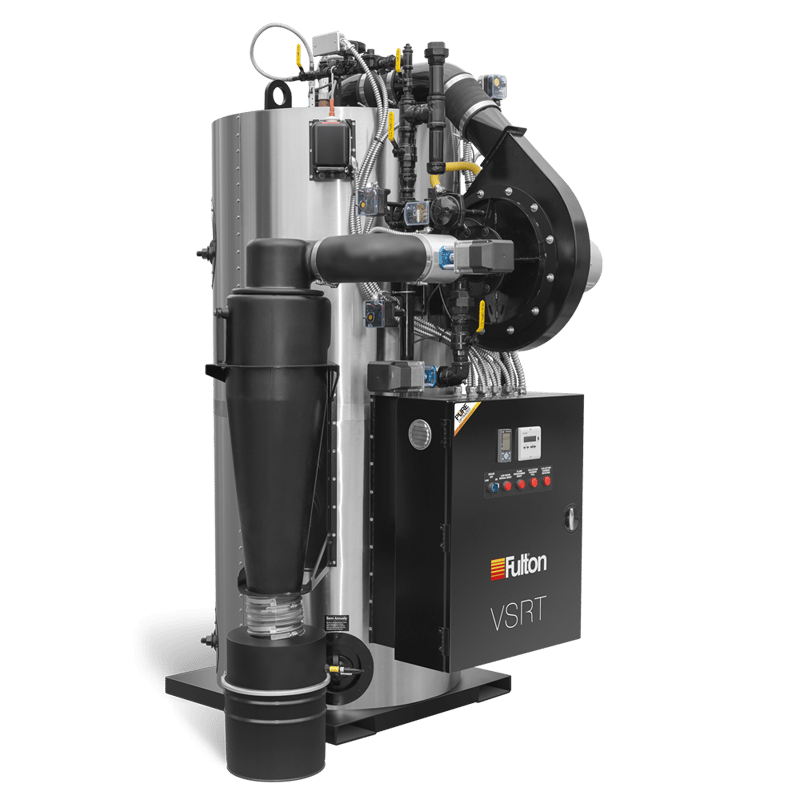

EASE OF OWNERSHIP

Our engineers considered every aspect when designing the VSRT. From high-grade controls and easy-to-access maintenance points, to our breakthrough cyclonic air filtration.

- INDUSTRIAL CONTROL PLATFORM

- EASY ACCESS TO THE PRESSURE VESSEL

- 5-YEAR BURNER WARRANTY

CUSTOM ENGINEERED SOLUTIONS

With extensive engineering experience, Fulton’s team can design and build a system tailored to your specific needs. From concept to delivery, you are part of the process, ensuring timely and accurate completion of your custom engineered system.

- INDUSTRY LEADER IN SYSTEMS ENGINEERING

- SINGLE-SOURCE TURNKEY SYSTEMS

- WIDE RANGE OF ANCILLARY EQUIPMENT

- 10 YEAR PRESSURE VESSEL WARRANTY